When the newly renovated Mukwonago High School welcomed students this fall, a critical component was a redesign of the school’s Career and Technical Education (CTE) spaces, which offer a combination of flexibility, engaging equipment, and intentional design.

“Our goal was to promote the acquisition of 21st century skills as much as possible,” said Mukwonago Schools Coordinator of College and Career Readiness Dustin Lehman. “We want students to problem solve, think critically, and work together. They can take those skills to any job in the future.”

The focus of the new CTE area is the fab lab, or fabrication laboratory, a broad space that gives students practical experience in project creation. “What sets the Mukwonago fab lab apart from other schools’ spaces is that our students can go from concept to design to prototype to production in the same area,” said Lehman.

Concept Development/Design

The instructional design space features multiple touch screen computers loaded with software to help students learn digital design. Students can create virtual walkthroughs of spaces they design or use the touch screen function to take digital notes and communicate their ideas in virtual meetings with local business leaders. Multiple displays allow teachers to demonstrate their coding while students can simultaneously see how the changes affect the digital product.

Prototyping

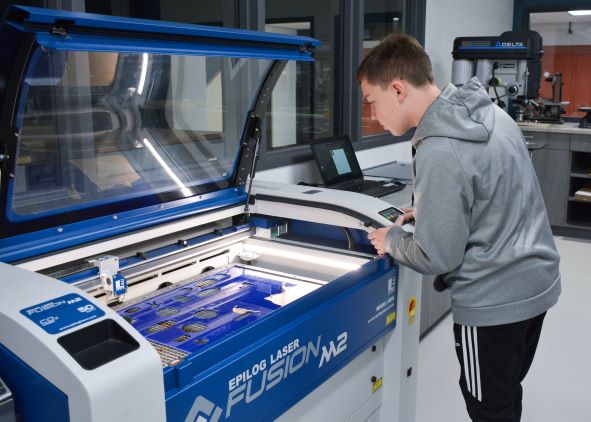

Located next to the design lab, the fab lab has equipment capable of turning students’ concepts into functioning prototypes: 3D printers, a CNC router, laser engravers, and a large format vinyl cutter printer, for example. Teachers can monitor both areas without sacrificing project supervision or student safety.

Production

The assembly space is designed to facilitate assembly and disassembly of projects, and to encourage collaboration. The space features large butcher block tables, a multi-touch interactive whiteboard, and large marker boards along with all the tools students might need.

Bringing It All Together

Intentional design of the CTE area makes project completion into a seamless process. Large transparent garage doors connect the spaces, making it easy to share ideas. Just steps away, art classrooms and the renovated machine shop, welding lab, and construction classrooms support collaboration across disciplines.

“Our goal is to create meaningful capstone courses where local manufacturers bring a problem, explain the specs and constraints to students, and then give students a chance to go through the design process to solve the problem,” said Director of Student Learning Nick Reichhoff. Students would complete their capstone project by presenting their solutions to potential employers in a bright new lecture hall capable of seating large groups.